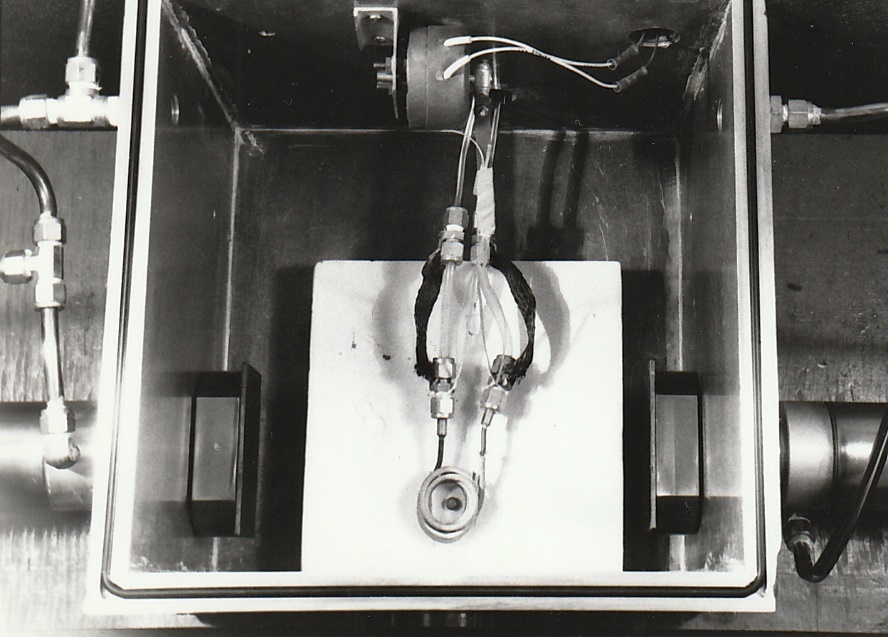

Materials Processing

in Space

Challenge: Identified material’s whose applications justify high cost of processing in low gravity.

Potential applications: Devices where resistance to demagnetization is critical (guidance systems, pacemakers, hearing aids, etc.) and usage amount is small enough to make the application insensitive to cost

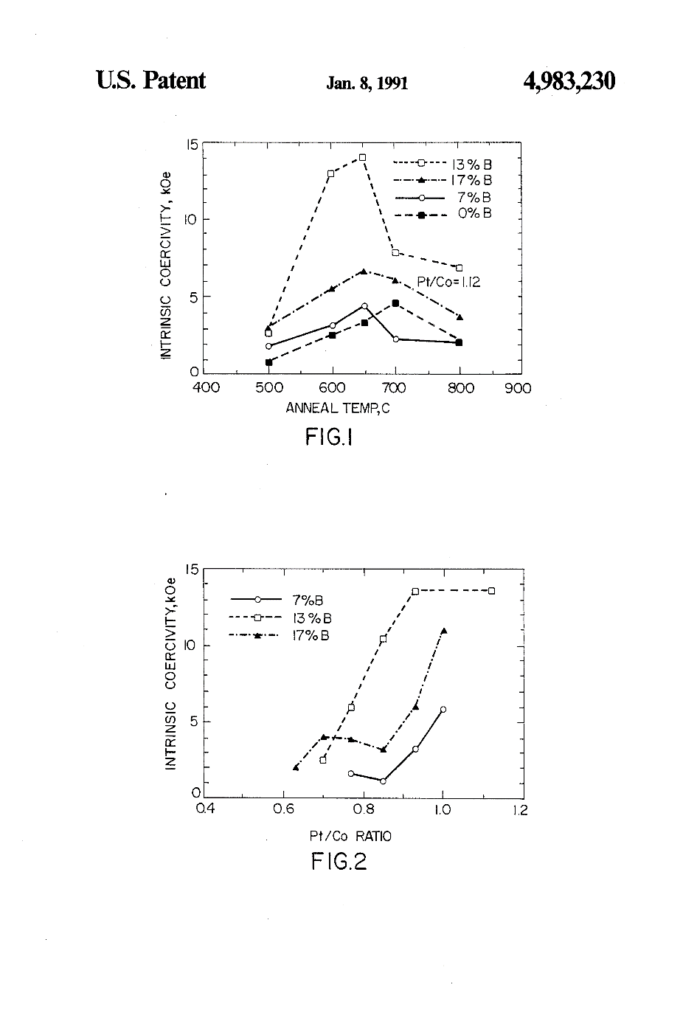

Working closely with professors & other graduate students at Vanderbilt University, developed and patented demagnetization resistant alloy formulation & a rapid solidification process to simulate processing in a micro-gravity environment. Resulting system was shown to be 3x more resistant to demagnetization that the standard, terrestrial alloy.

Effort was funded by NASA & industry to demonstrate the commercial feasibility of processing high value materials in space.

Patent 4983230

High Perfomance

Sink Material

Challenge: Developed cost effective, proprietary composite material with industry leading performance

Hands-on member of team that adapted a manufacturing process from an unrelated industry and subsequently engineered material formulations in a wide range of colors to produce sinks with superior impact, stain, & scratch resistance at lower cost than competitive products.

The system enabled molding capabilities not feasible with other materials & processes.

The formulation was developed in close collaboration LCA practitioners to ensure sustainability was designed into the material & mfg. process from the outset of the project

Patent 9650490

Manual

Bidet seat

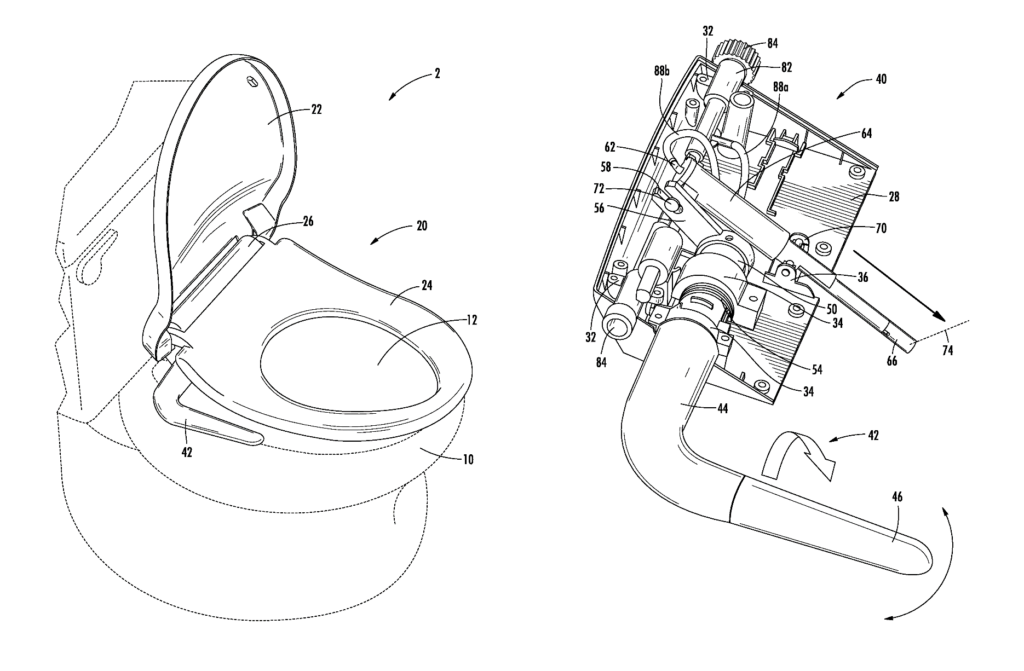

Challenge: Developed a low-cost bidet seat with functionality equal to or better than electronic seats.

Collaborated closely with industrial designers & engineers to package the seat design around an innovative, yet simple mechanism that controls the direction & flow of the water. Resulting product was priced at ¼ that of competitive (electric) bidet seats with superior water flow & directional control

Patent 9976293

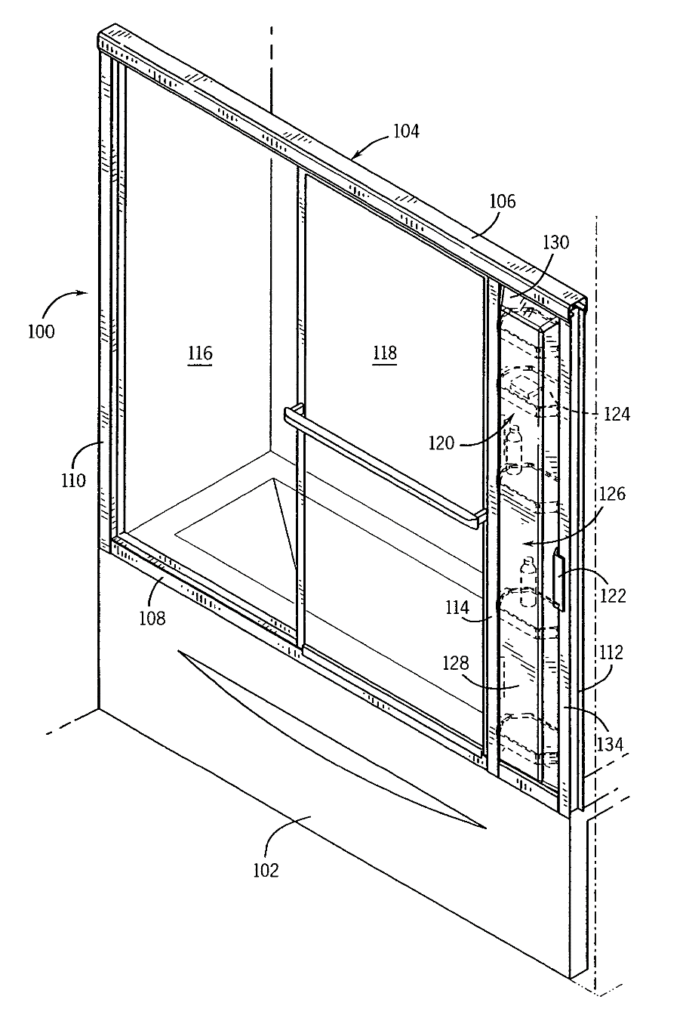

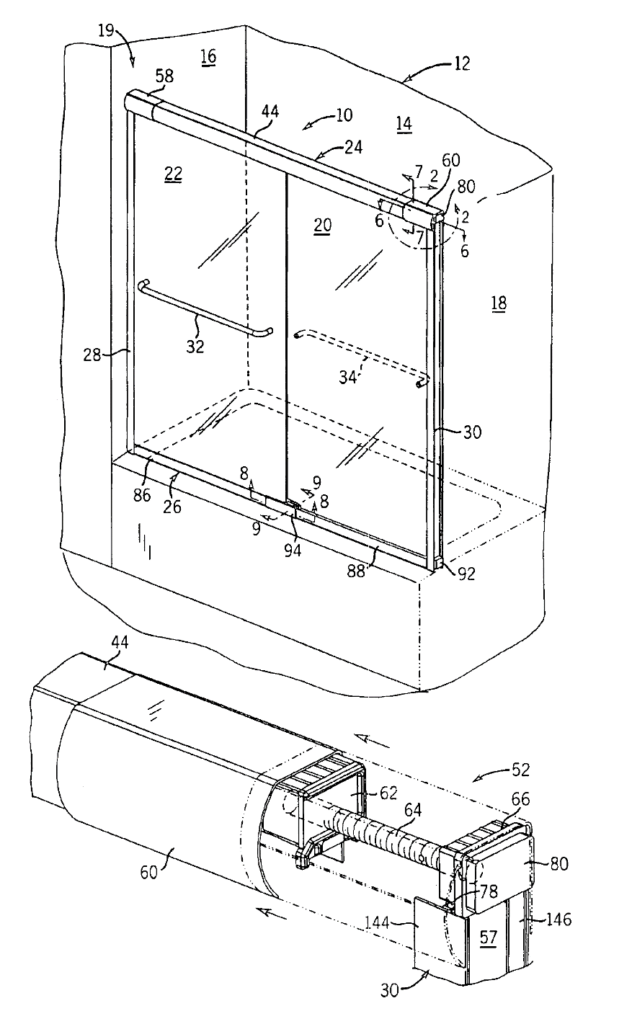

Storage & Quick

install Shower Doors

Challenge: Enhanced the functionality of shower doors to drive differentiation in a commoditized space

Added storage to the door without compromising entry & egress. Worked closely with the operator of the largest injection molding press in the US at the time to ensure a seamless, uniform storage column

Patent 8707475

Enabled door to be installed without drilling into bath fixture or wall surround. Worked closely with the six-sigma team to design experiments to ensure the design’s robustness

Patents: 6895714 & 6701672